BGA Assembly

HOME > SERVICES > PCB Assembly > BGA Assembly

PORTOWER: Your Expert Partner for BGA & Micro-BGA PCB Assembly

As electronics continue trending toward miniaturization and higher performance, BGA technology has become essential for achieving high-density component placement. PORTOWER specializes in advanced BGA and Micro-BGA assembly, delivering reliable interconnections and superior signal integrity for today’s most demanding applications.

- Advanced capability in BGA and Micro-BGA assembly

- Comprehensive testing including 100% E-Test, AOI, ICT, and FCT

- ISO9001: 2015 certified & UL listed facilities

- Compliance with IPC A-610 Class 2 & 3 standards

- Flexible full turnkey and partial turnkey solutions

PORTOWER: Your Expert Partner for BGA & Micro-BGA PCB Assembly

As electronics continue trending toward miniaturization and higher performance, BGA technology has become essential for achieving high-density component placement. PORTOWER specializes in advanced BGA and Micro-BGA assembly, delivering reliable interconnections and superior signal integrity for today’s most demanding applications.

- Advanced capability in BGA and Micro-BGA assembly

- Comprehensive testing including 100% E-Test, AOI, ICT, and FCT

- ISO9001: 2015 certified & UL listed facilities

- Compliance with IPC A-610 Class 2 & 3 standards

- Flexible full turnkey and partial turnkey solutions

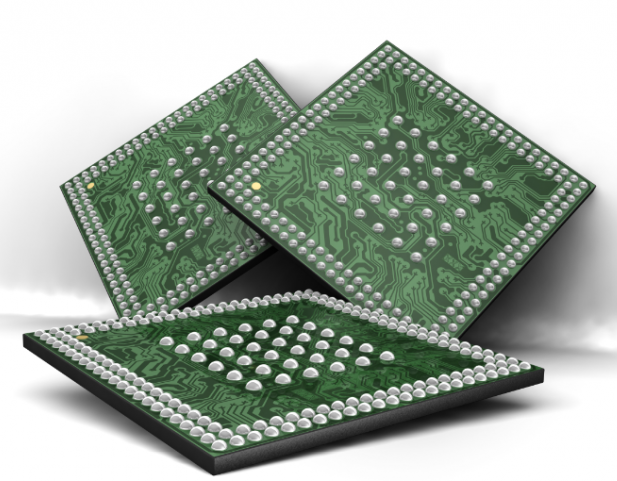

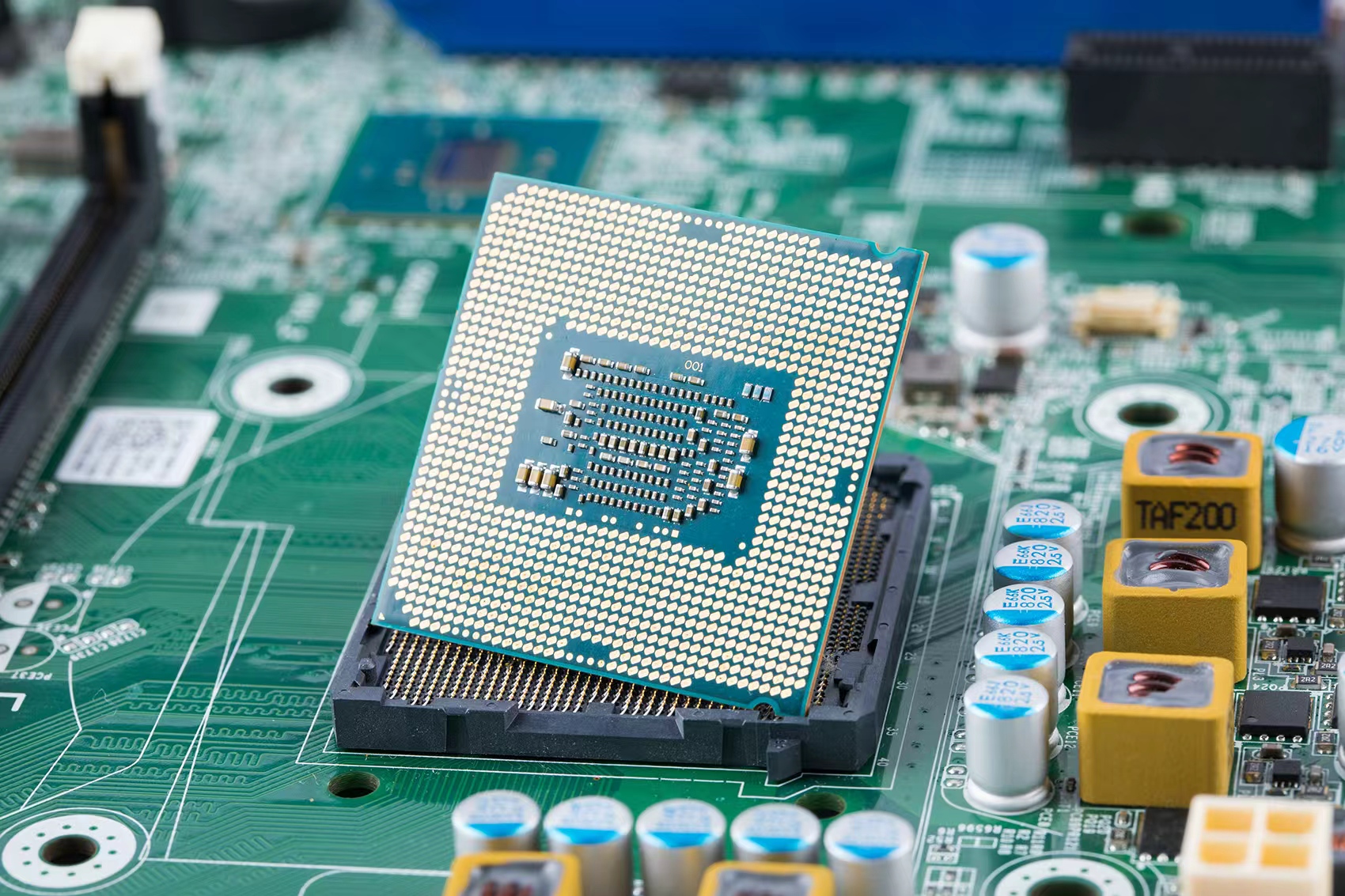

What is a BGA (Ball Grid Array) and Why Should You Care?

Key Advantages of BGA:

Superior Density

With connections across the entire underside, BGA can accommodate hundreds or even thousands of I/Os in a compact space, enabling miniaturization of your end product.

Enhanced Electrical Performance

Shorter leads result in lower inductance and better electrical characteristics. This is critical for high-speed processors, FPGAs, and memory, ensuring signal integrity and reducing power consumption.

Improved Thermal Performance

The chip die can efficiently transfer heat through the substrate to the solder balls and the PCB. This allows for better heat dissipation, leading to higher reliability and stability.

The Evolution of Electronic Technology: The Role of BGA

As technology advances, BGA design guidelines have become increasingly important, demonstrating their adaptability and significance.

Early Applications: High-Performance Computing

BGA was initially used in high-speed computing, providing efficient, reliable, and compact connectivity.

Mobile Era: Laptops and Smartphones

BGA played a key role in developing thin and light devices, improving speed and responsiveness by shortening connection paths.

Wearable Device Revolution

BGA is essential in devices such as smartwatches and fitness trackers, where its small size and efficient thermal management are crucial.

Internet of Things (IoT): The Era of Connected Devices

BGA is tailored for a wide range of IoT devices, from smart thermostats to connected refrigerators, ensuring stable and efficient connectivity for seamless data transmission.

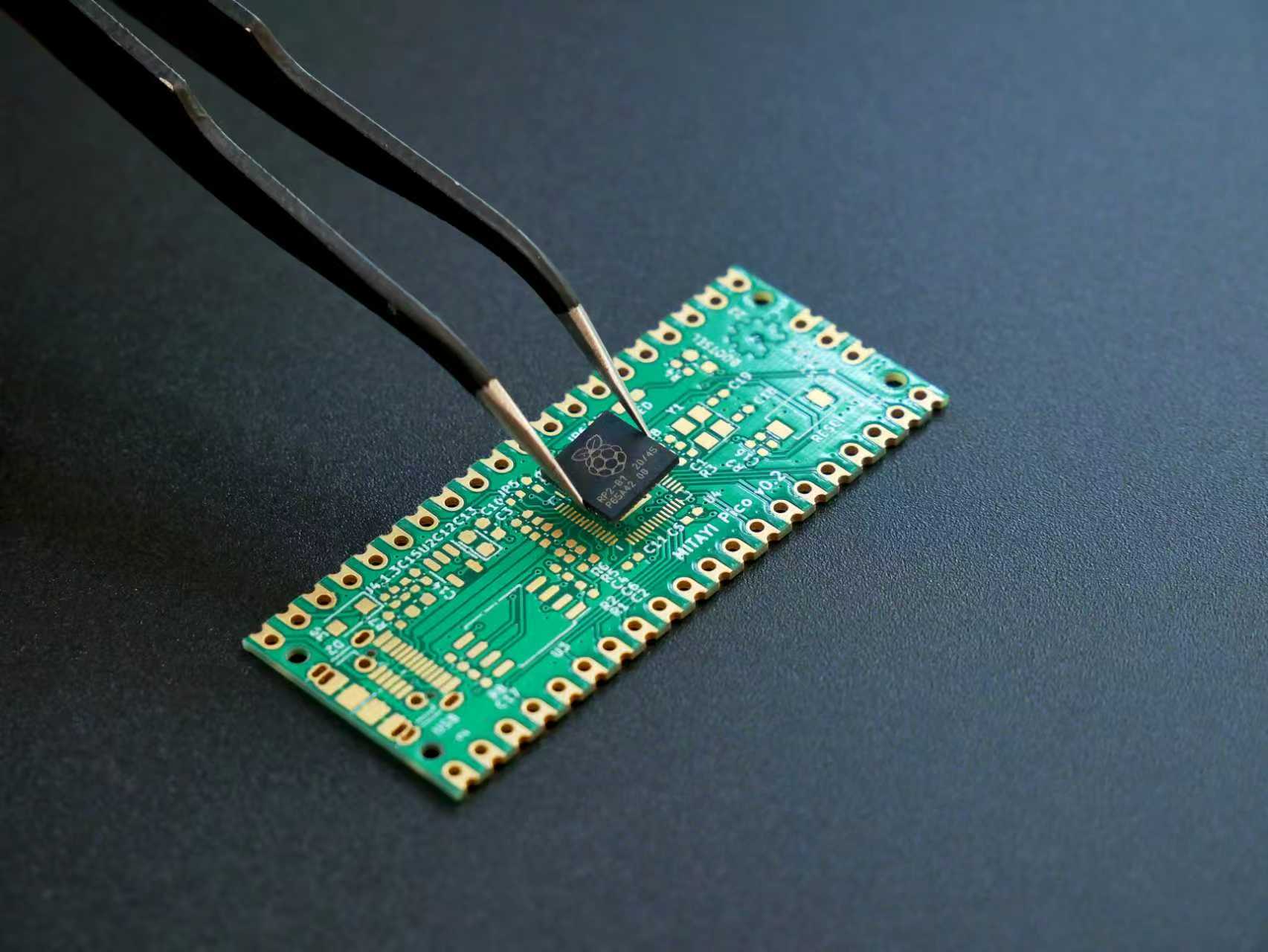

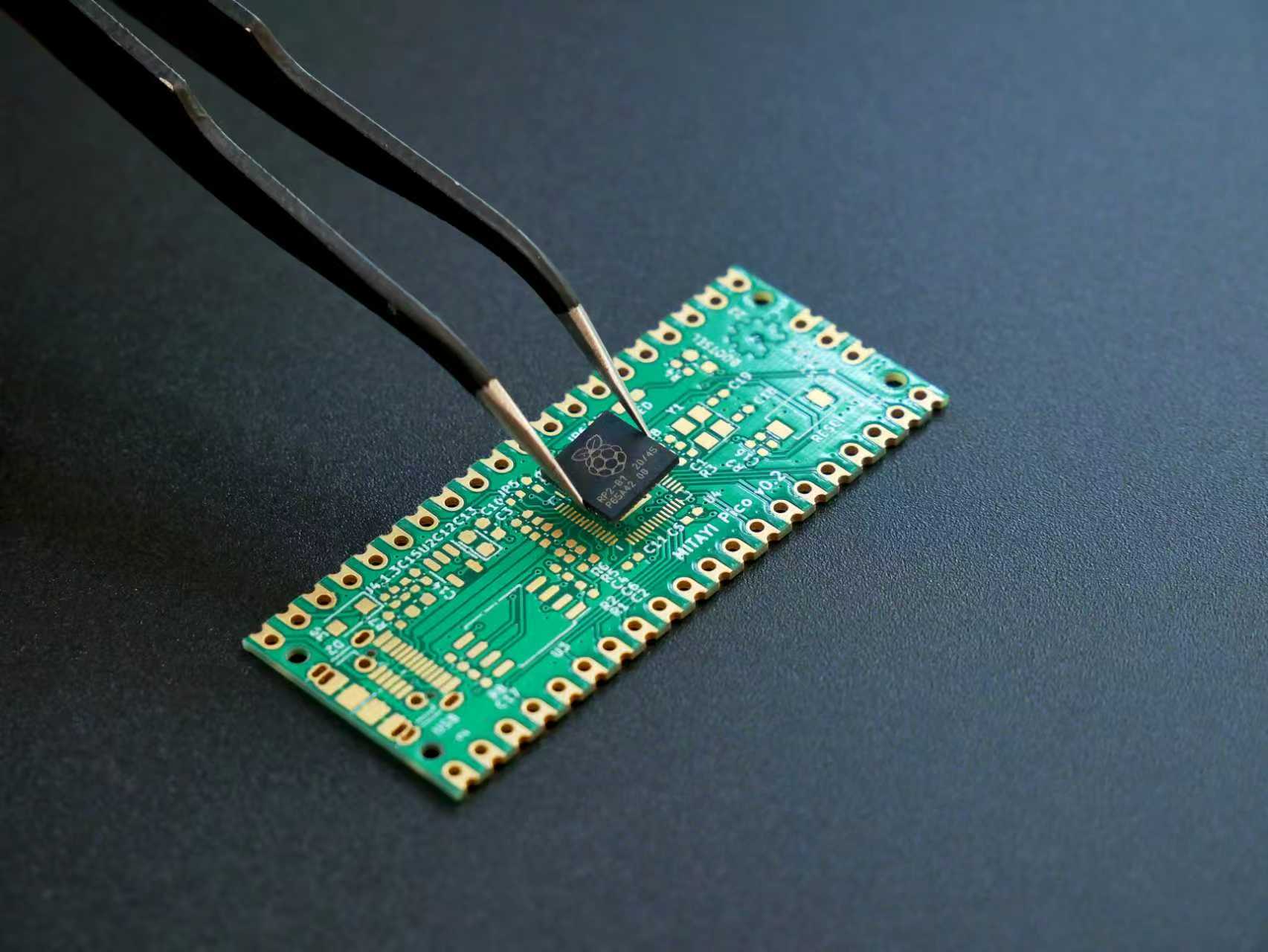

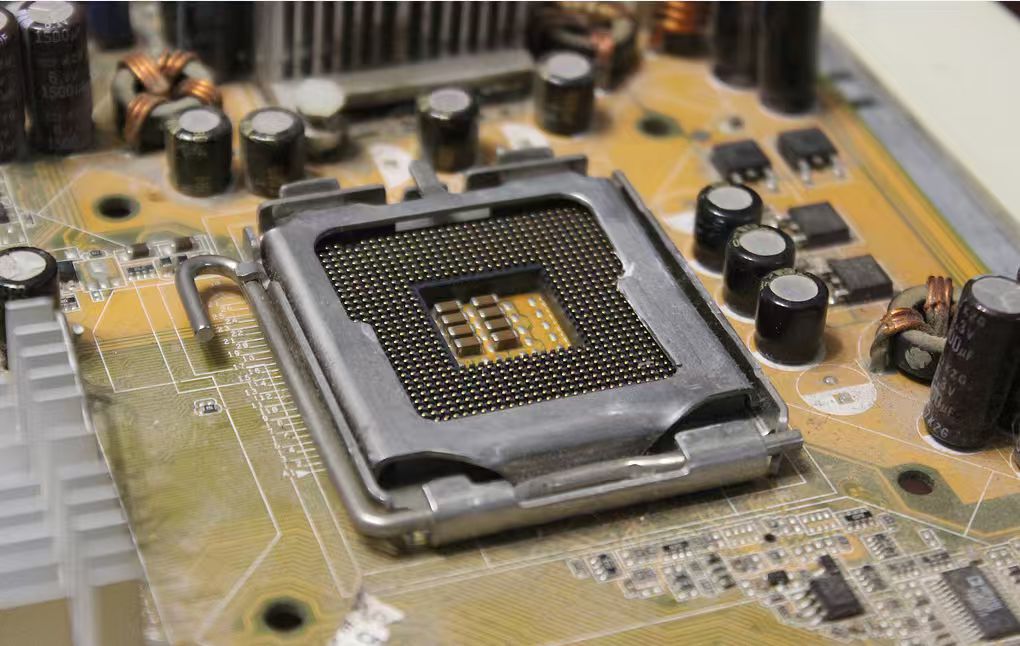

BGA Inspection: How We Check Hidden Solder Joints

You Can’t See BGA Solder Joints. We Can. After a BGA is soldered, the connections are hidden underneath. This is the biggest challenge. We use advanced technology to look inside and guarantee quality.

Our Inspection Process:

Solder Paste Inspection (SPI) - Prevention First

- What: We scan the solder paste before placing the BGA.

- Why: To ensure the right amount of paste is applied. This prevents most defects before they happen.

X-Ray Inspection (AXI) - Seeing the Unseeable

- What: We use X-rays to see through the BGA and check the hidden solder balls.

- Why: This is the only way to find critical defects like voids, bridges, or poor connections. We check every single ball.

Functional Test (FCT) - The Final Proof

- What: We power up the board and test its functions.

- Why: To make sure the BGA not only is soldered correctly but also works perfectly with the rest of the circuit.