Box Build Assembly

HOME > SERVICES > PCB Assembly > Box Build Assembly

PORTOWER: Precision Box Build Assembly Solutions

PORTOWER delivers exceptionally engineered box build assemblies through rigorous process control and continuous engineering oversight, ensuring flawless integration at every stage.

- Flexible payment terms to suit your needs

- Detailed CAM review provided before manufacturing

- Comprehensive technical support for all your PCB requirements

- Product samples available before bulk order commitment

- 24/7 access to experienced engineering support

PORTOWER: Precision Box Build Assembly Solutions

PORTOWER delivers exceptionally engineered box build assemblies through rigorous process control and continuous engineering oversight, ensuring flawless integration at every stage.

- Flexible payment terms to suit your needs

- Detailed CAM review provided before manufacturing

- Comprehensive technical support for all your PCB requirements

- Product samples available before bulk order commitment

- 24/7 access to experienced engineering support

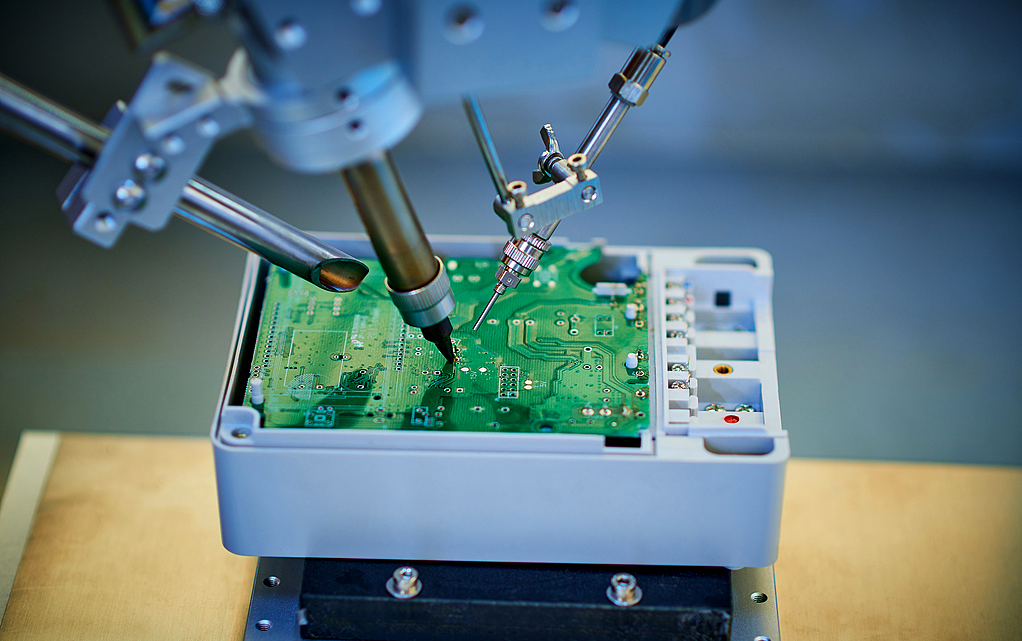

Box Build Assembly

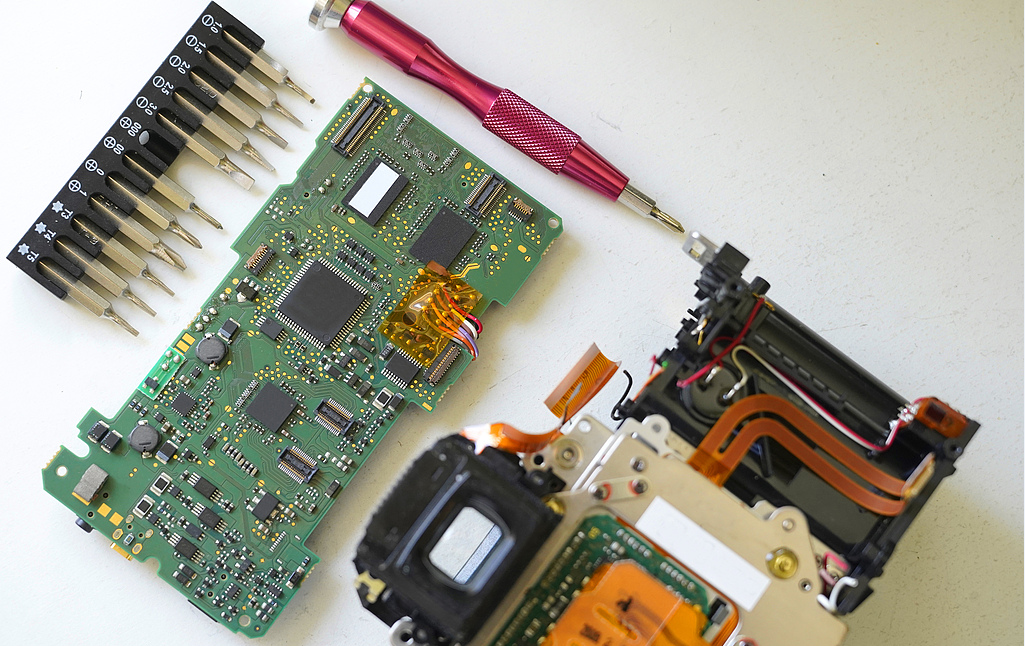

Box Build is more than just putting parts in an enclosure. It’s the integration of PCBAs, wiring, pneumatics, and software into a fully functional, tested, and ready-to-ship system. Our services include but are not limited to:

PCB Assembly Integration

Seamlessly incorporating your supplied or our sourced PCBAs.

Wire Harness & Cable Assembly

Custom-designed and fabricated to ensure flawless connectivity.

Software Loading & Configuration

Installing and configuring your firmware or operating system.

System-Level Testing & Burn-in

Functional testing, safety certification (UL/CE), and performance validation.

Final Packaging & Logistics

Custom packaging, kitting, and worldwide shipping.

We take ownership of the entire process, managing complexity and supply chain risks so you can focus on innovation and market expansion.

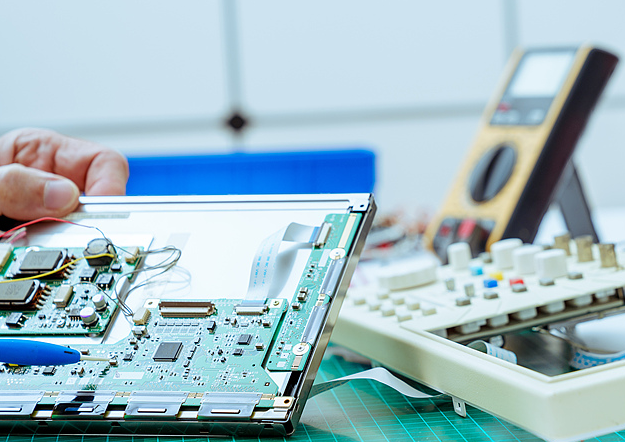

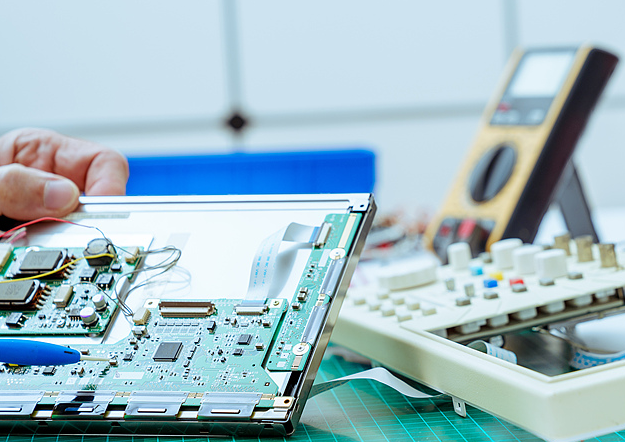

Rigorous Testing: The Core of Reliable Box Build Assembly

While crucial for any PCB, testing is absolutely vital for a complete Box Build Assembly. At PORTOWER, our quality assurance process incorporates a suite of advanced testing methodologies to guarantee integrity from the board level up to the final product:

AOI:

For high-speed, precision verification of component placement and solder joint quality on your PCBAs.

Automated X-Ray Inspection (AXI):

To peer beneath the surface and uncover hidden defects in BGAs and other complex, concealed connections.

Flying Probe Testing:

For efficient and accurate electrical performance validation, perfect for prototypes and mid-volume production without the need for costly custom fixtures.

Solder Float Test:

A critical stress test for solder joint integrity, ensuring long-term reliability and resistance to failure.

Functional Test:

The final validation, where the completely assembled box is powered on and tested under simulated operational conditions to ensure it meets all functional specifications.