Medical PCBA

HOME > SERVICES > PRODUCT > Medical PCBA

PORTOWER: Your Expert Partner for Medical PCB Solutions

With over 6+ years of dedicated service, PORTOWER has earned global recognition for delivering exceptional reliability and premium quality PCBs to the medical industry. Our commitment to excellence ensures that every project meets the highest standards of performance and precision.

- 100% inspection coverage including AOI and E-Test

- Comprehensive custom PCB solutions and support

- Readily available raw material inventory

- 24/7 customer service availability

- Sample units provided prior to bulk production

PORTOWER: Your Expert Partner for Medical PCB Solutions

With over 6+ years of dedicated service, PORTOWER has earned global recognition for delivering exceptional reliability and premium quality PCBs to the medical industry. Our commitment to excellence ensures that every project meets the highest standards of performance and precision.

- 100% inspection coverage including AOI and E-Test

- Comprehensive custom PCB solutions and support

- Readily available raw material inventory

- 24/7 customer service availability

- Sample units provided prior to bulk production

Related Product Recommendations

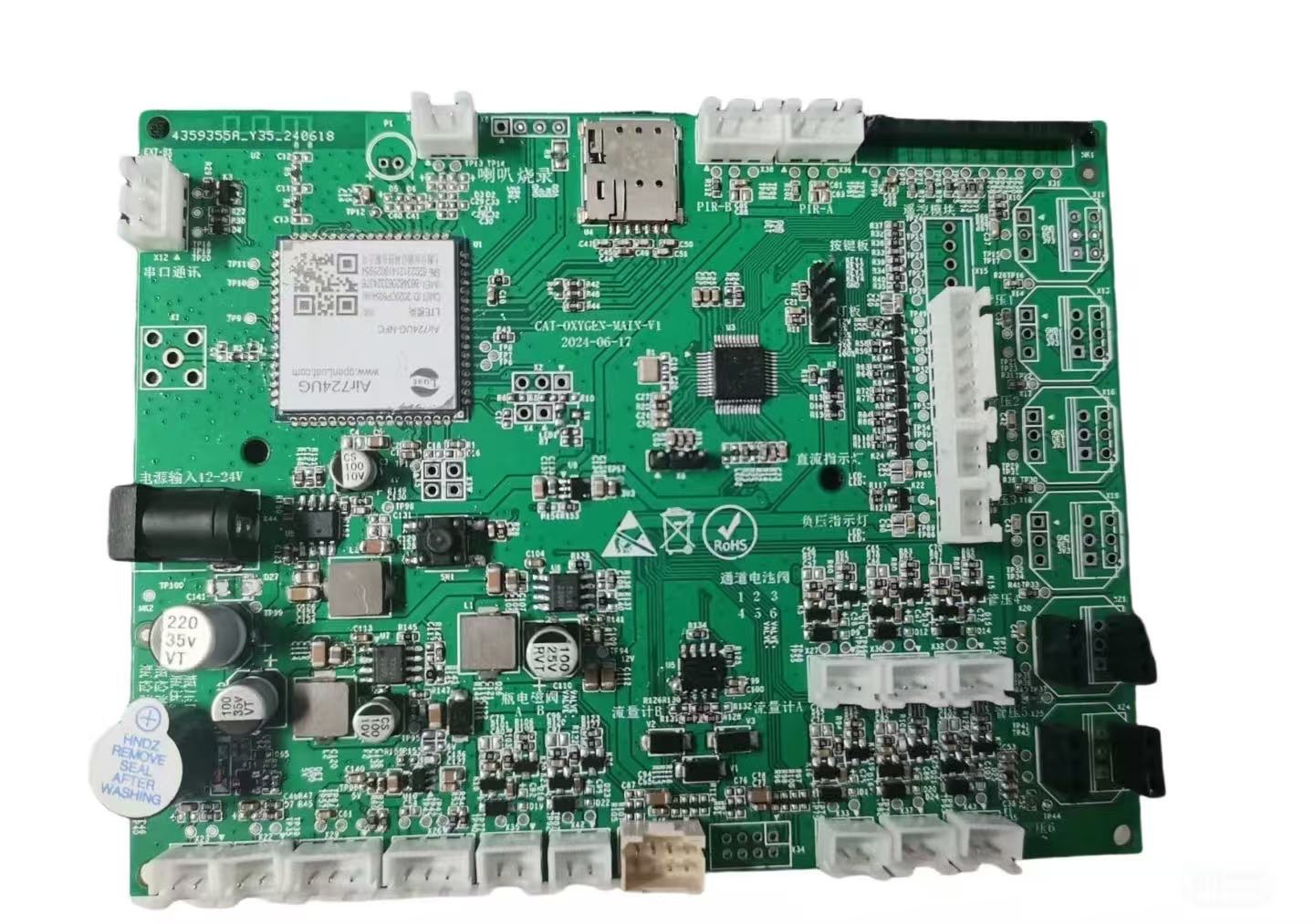

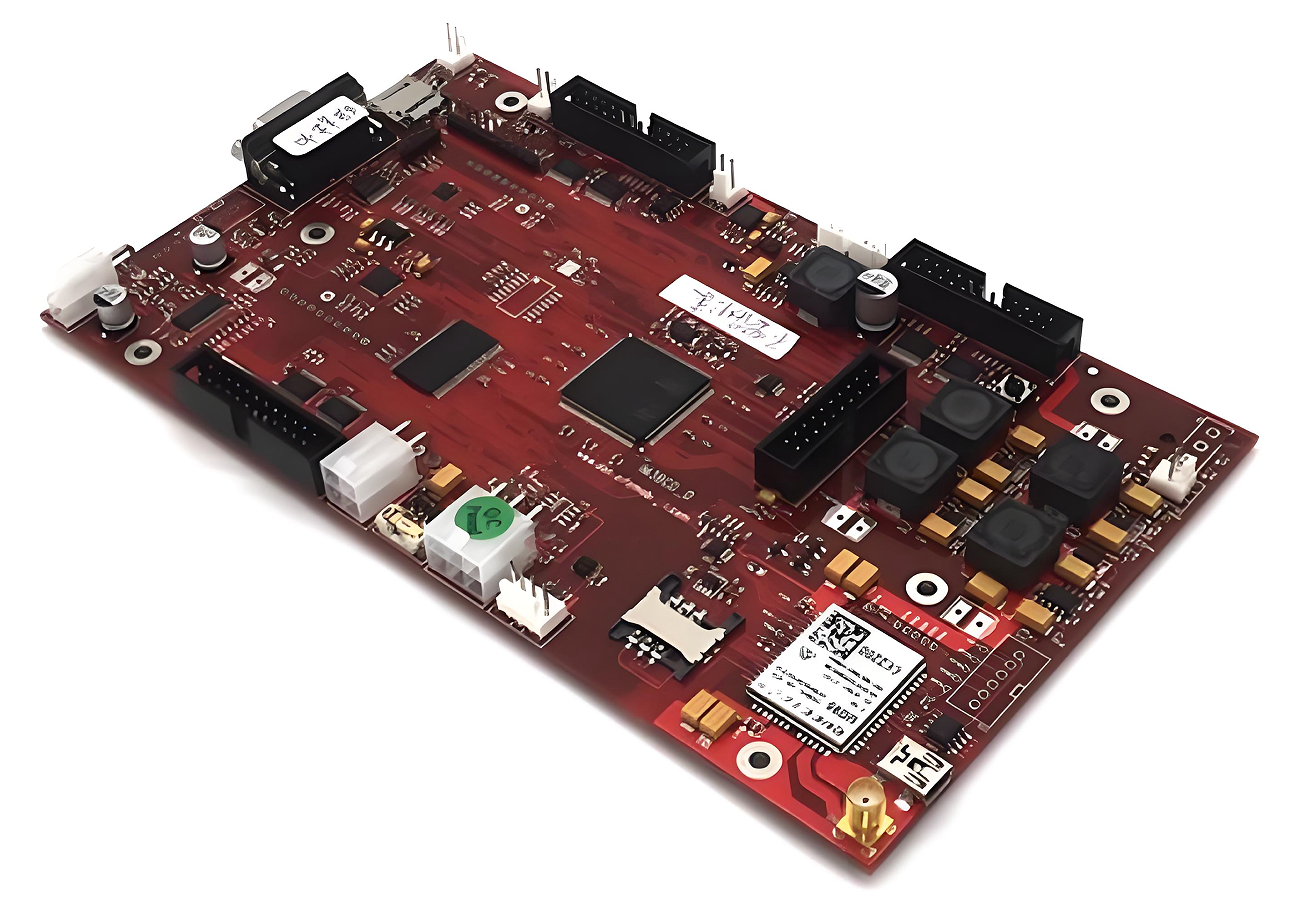

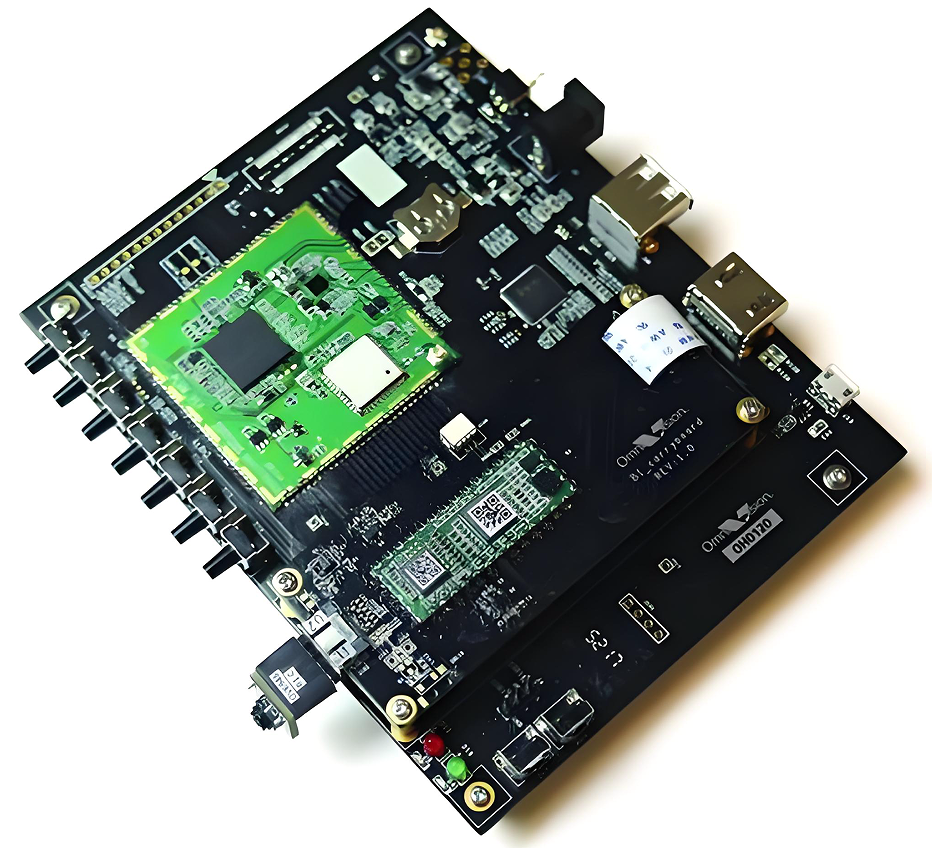

Precision Medical Equipment PCBA ROHS PCB Assembly

Ultrasonic Atomizer PCB Assembly

Image Signal Processor Medical PCBA

Product Details

Introduction:

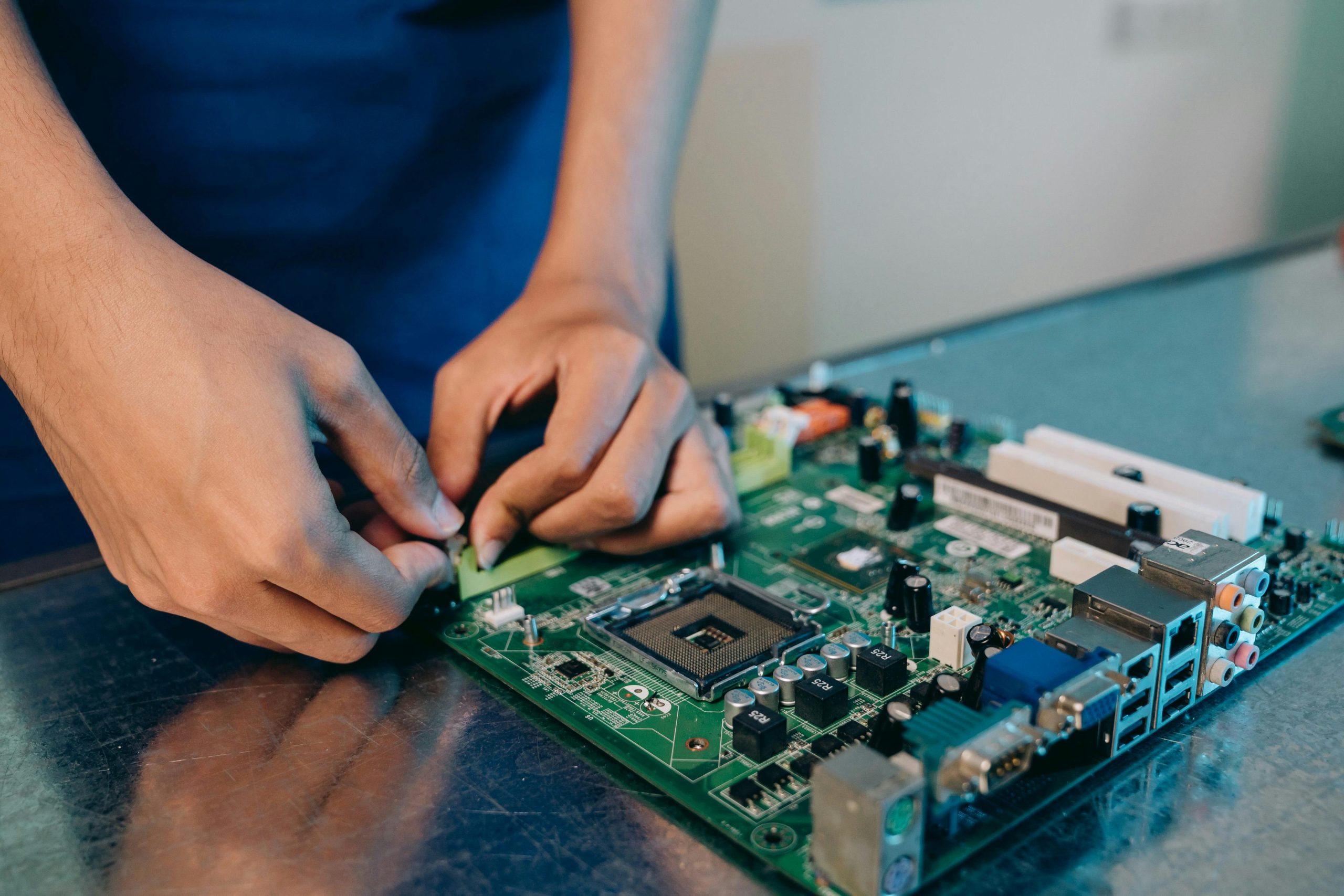

Medical Electronics PCB Assembly is the highly specialized process of designing, manufacturing, and testing circuit boards for the healthcare industry. These assemblies form the electronic backbone of a vast range of equipment, from portable diagnostic tools to life-sustaining systems.

In an industry where reliability is paramount, medical PCB assemblies must meet the highest standards of quality, precision, and regulatory compliance. This commitment ensures patient safety and device efficacy.

Key requirements include:

- Use of medical-grade and often biocompatible materials.

- Strict adherence to ISO 13485, IPC-A-610 Class 3, and FDA 21 CFR Part 820.

- Rigorous testing protocols and full component traceability.

- Complex, high-density interconnect (HDI) and miniaturized designs.

These advanced PCBs enable critical functions like real-time data processing, wireless connectivity, and precise sensor integration, powering innovations in remote patient monitoring, robotic surgery, and advanced imaging.

Why PCBs are Indispensable in Medical Electronics

Printed Circuit Boards are the fundamental building blocks of modern medical technology. Their performance directly impacts the accuracy of diagnostics, the effectiveness of treatments, and ultimately, patient outcomes.

Key Areas of Impact:

1. The Core of Life-Critical Devices

PCBs provide the reliable functionality required by equipment where failure is not an option. They are the foundation of:

- Diagnostic & Monitoring Systems: ECG/EKG machines, patient vital signs monitors.

- Therapeutic & Life-Support Devices: Defibrillators, infusion pumps, ventilators.

- Advanced Medical Imaging: MRI, CT Scanners, and X-ray systems.

- Surgical & Implantable Tools: Robotic surgical systems, pacemakers, neurostimulators.

2. Enabling Precision and Miniaturization

Modern medical devices demand smaller, faster, and more powerful electronics. Advanced PCBs make this possible through:

- High-Density Interconnect (HDI): Packing more functionality into a smaller footprint.

- Flexible and Rigid-Flex PCBs: Allowing for ergonomic and compact device designs.

- Advanced Signal Integrity: Ensuring accurate data acquisition from sensitive sensors.

3. Ensuring Compliance and Patient Safety

Beyond functionality, medical PCBs are designed for unparalleled safety and reliability, incorporating features like:

- Fail-Safe Designs and Redundancies

- Biocompatible Materials for implants and skin-contact devices.

- EMI/EMC Shielding to prevent interference with other critical equipment.

- Full Documentation for audit trails and regulatory submissions.