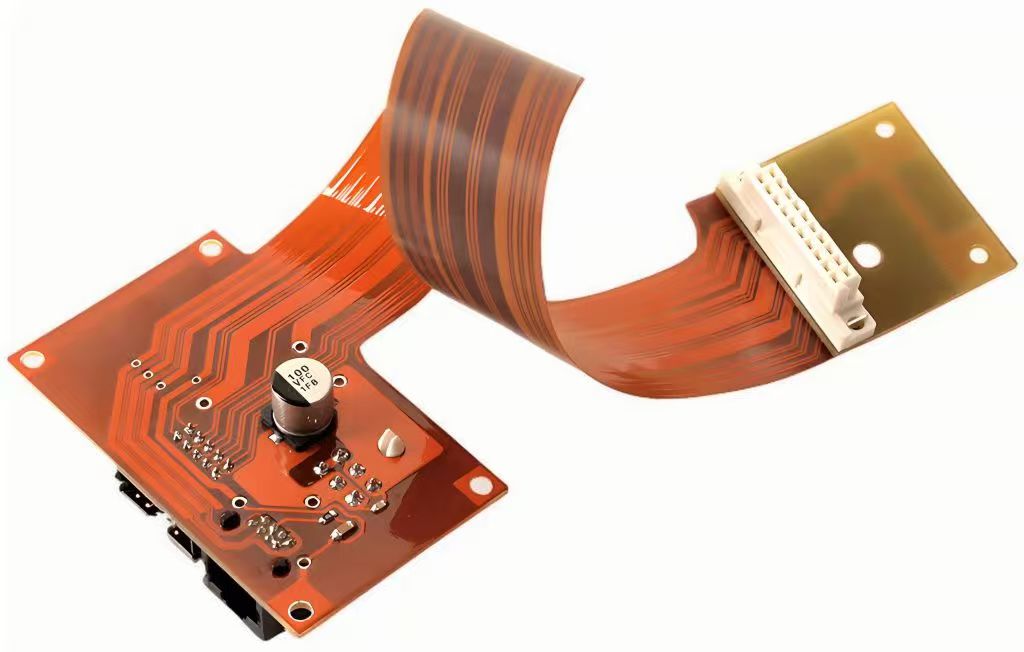

Why “Bendy” is the New “Brilliant”

Think about the last time you had to cram a square peg (a rigid PCB) into a round hole (your sleek, curved product design). You probably ended up with:

- A tangle of wires and connectors.

- Compromises on size or battery life.

- Nagging worries about vibration and reliability.

Flex circuits cut through these problems like a hot knife through butter. They’re the wire you don’t have to solder, the connection that doesn’t need a connector.

The “Aha!” Moments We Love to See

Some of our favorite projects aren’t about the technology itself, but about the problem it killed. Like when a client:

- Replaced an entire 5 – board, cable – harnessed mess in a medical sensor with one elegant Rigid – Flex unit. Reliability went up, assembly time plummeted.

- Designed a wearable that molds perfectly to the body, because the circuit could bend with the user, not fight against them.

- Saved 40% of the internal space in a drone, allowing for a bigger battery and longer flight time, just by letting the PCB fold into the contours of the frame.

The magic isn’t in the bend—it’s in the freedom the bend provides.

But Let’s Be Real: It’s Not Magic, It’s Expertise.

Switching to flex isn’t like ordering a different pizza topping. A successful flex design lives or dies in the CAD stage. Get the bend radius wrong? It’s toast. Choose the wrong stiffener material? Problems.

That’s why we don’t just build your flex designs; we partner on them. Our best work starts with the question: “What are you trying to achieve?” long before we talk about materials or quotes.

So, Is Your Next Project a “Flex” Candidate?

Ask yourself these questions:

- Is my product constantly moving, bending, or vibrating?

- Am I fighting for every cubic millimeter of space?

- Does my BOM have more connectors than I’d like?

- Is reliability the #1 non – negotiable?

If you nodded to any of these, it’s time to have a conversation about going flexible.

The Future Isn’t Stiff

The trend is clear: products are getting smarter, smaller, and more integrated. The rigid board will always have its place, but the growth—the real innovation—is happening in the third dimension.

We’re here to help you build that future. Not just with manufacturing muscle, but with the design insight to make it work flawlessly.

Feeling inspired? Or just curious?

What product have you seen that made you think, “Wow, how did they fit the electronics in that?” Reply and let us know – we love a good design mystery.