Rigid-Flex/Flex-PCB-Assembly

HOME > SERVICES > PCB Assembly > Rigid-Flex/Flex-PCB-Assembly

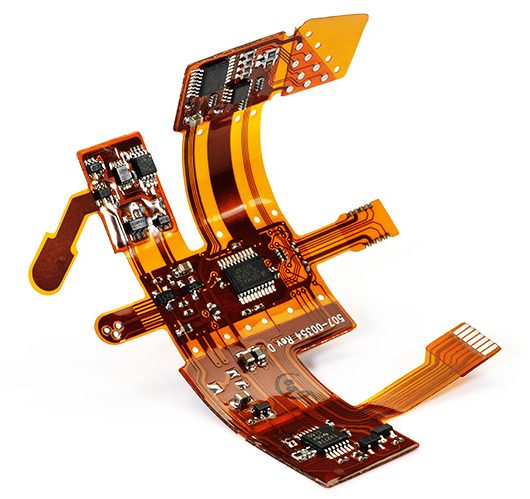

PORTOWER: Your Trusted Partner for Reliable Flex PCB Assembly

PORTOWER’s Flex PCB Assembly solutions have earned global recognition for their outstanding performance and durability in demanding applications.

- Receive expert responses to technical inquiries within 1-2 hours

- Benefit from our dedicated support throughout your custom flex PCB project

- All assemblies comply with IPC Class 2 & 3 quality standards

- 100% inspection coverage including E-Test and AOI

- 24/7 professional technical support available

PORTOWER: Your Trusted Partner for Reliable Flex PCB Assembly

PORTOWER’s Flex PCB Assembly solutions have earned global recognition for their outstanding performance and durability in demanding applications.

- Receive expert responses to technical inquiries within 1-2 hours

- Benefit from our dedicated support throughout your custom flex PCB project

- All assemblies comply with IPC Class 2 & 3 quality standards

- 100% inspection coverage including E-Test and AOI

- 24/7 professional technical support available

Why Choose Flexible PCB Assembly?

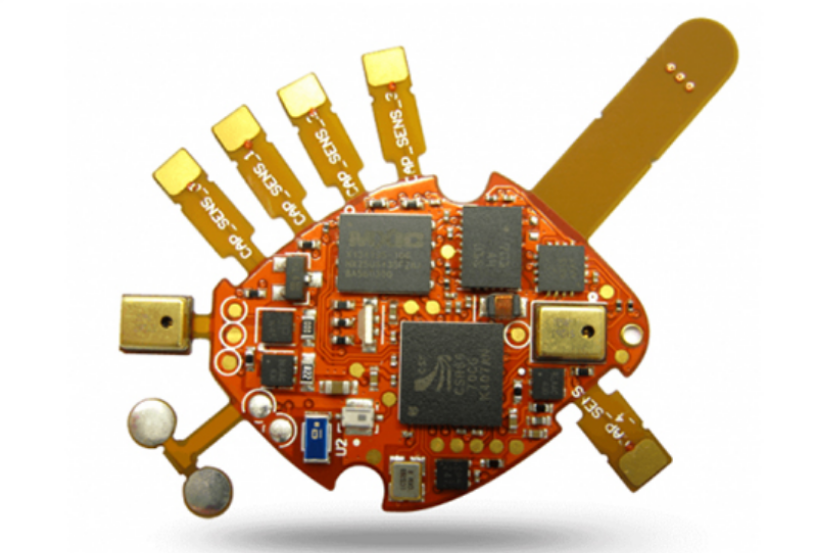

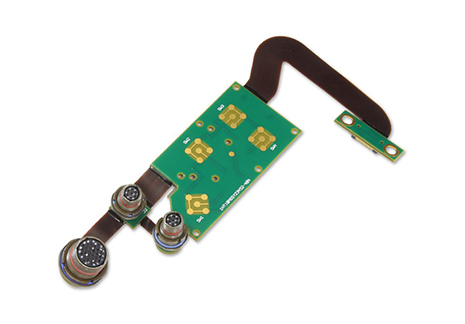

Imagine a circuit board made of a durable, high-performance plastic film (like Kapton), with thin copper traces etched onto it. This is the essence of a flexible PCB.

They are not just “bent boards” – they are engineered from the ground up to be dynamic and three-dimensional.

3D Packaging

Fold and shape the circuit to fit your product’s unique enclosure, saving crucial space.

Lightweight & Thin

Ideal for drones, wearables, and medical devices where every gram and millimeter counts.

High Reliability

Fewer interconnects and connectors mean fewer potential points of failure. They withstand millions of bending cycles (in dynamic applications).

Durability

Superior resistance to vibration and shock compared to rigid boards.

Design Freedom

Combine multiple rigid boards into a single, integrated flex assembly, simplifying your supply chain.

Our Expertise: It's More Than Just Assembly

Assembling flex circuits requires specialized knowledge. We ensure success by focusing on:

Design for Manufacturability (DFM) Review

We analyze your flex design early to prevent costly errors, advising on bend radii, stiffener placement, and material selection.

Specialized Handling

We use fixtures and processes to securely hold delicate flex circuits during assembly.

Precision Soldering Profile

Flex materials are heat-sensitive. We use precise reflow profiles to prevent delamination or damage.

Robust Testing

We perform electrical testing (Flying Probe) and visual inspection to guarantee reliability, even in the most demanding conditions.

Our Expertise: It's More Than Just Assembly

Assembling flex circuits requires specialized knowledge. We ensure success by focusing on:

Design for Manufacturability (DFM) Review

We analyze your flex design early to prevent costly errors, advising on bend radii, stiffener placement, and material selection.

Specialized Handling

We use fixtures and processes to securely hold delicate flex circuits during assembly.

Precision Soldering Profile

Flex materials are heat-sensitive. We use precise reflow profiles to prevent delamination or damage.

Robust Testing

We perform electrical testing (Flying Probe) and visual inspection to guarantee reliability, even in the most demanding conditions.

Why Choose Rigid-Flex? Solve Your Toughest Design Challenges.

Rigid-Flex Solution

- Space & Weight Constraints:Replaces bulky connectors and cables. Folds into tight, custom shapes.

- High-Vibration Environments:Eliminates the most common point of failure: board-to-board connectors.

- Complex 3D Assembly:Pre-formed to fit your unique enclosure, simplifying final assembly.

- Demanding Signal Performance:Continuous copper from rigid to flex reduces signal loss and impedance issues.

Benefit to You

- Enables ultra-compact, lightweight products (e.g., drones, medical implants).

- Dramatically improved reliability for automotive, aerospace, and industrial applications

- Reduces assembly time and cost, and minimizes human error.

- Superior signal integrity for high-speed applications.