Security PCBA

HOME > SERVICES > PRODUCT > Security PCBA

PORTOWER: Your Trusted Partner for Security PCB Manufacturing

As a specialized PCB manufacturer, PORTOWER possesses extensive expertise in producing high-reliability circuit boards for the security industry. We understand the critical role that PCBs play in security systems, and we are committed to delivering solutions that ensure uninterrupted protection and performance.

Our Security PCB Applications Include:

- Access control systems and electronic locks

- Intrusion detection and alarm systems

- Fire alarm and emergency notification systems

- Surveillance equipment and video monitoring devices

- Perimeter protection and entry management systems

PORTOWER: Your Trusted Partner for Security PCB Manufacturing

As a specialized PCB manufacturer, PORTOWER possesses extensive expertise in producing high-reliability circuit boards for the security industry. We understand the critical role that PCBs play in security systems, and we are committed to delivering solutions that ensure uninterrupted protection and performance.

Our Security PCB Applications Include:

- Access control systems and electronic locks

- Intrusion detection and alarm systems

- Fire alarm and emergency notification systems

- Surveillance equipment and video monitoring devices

- Perimeter protection and entry management systems

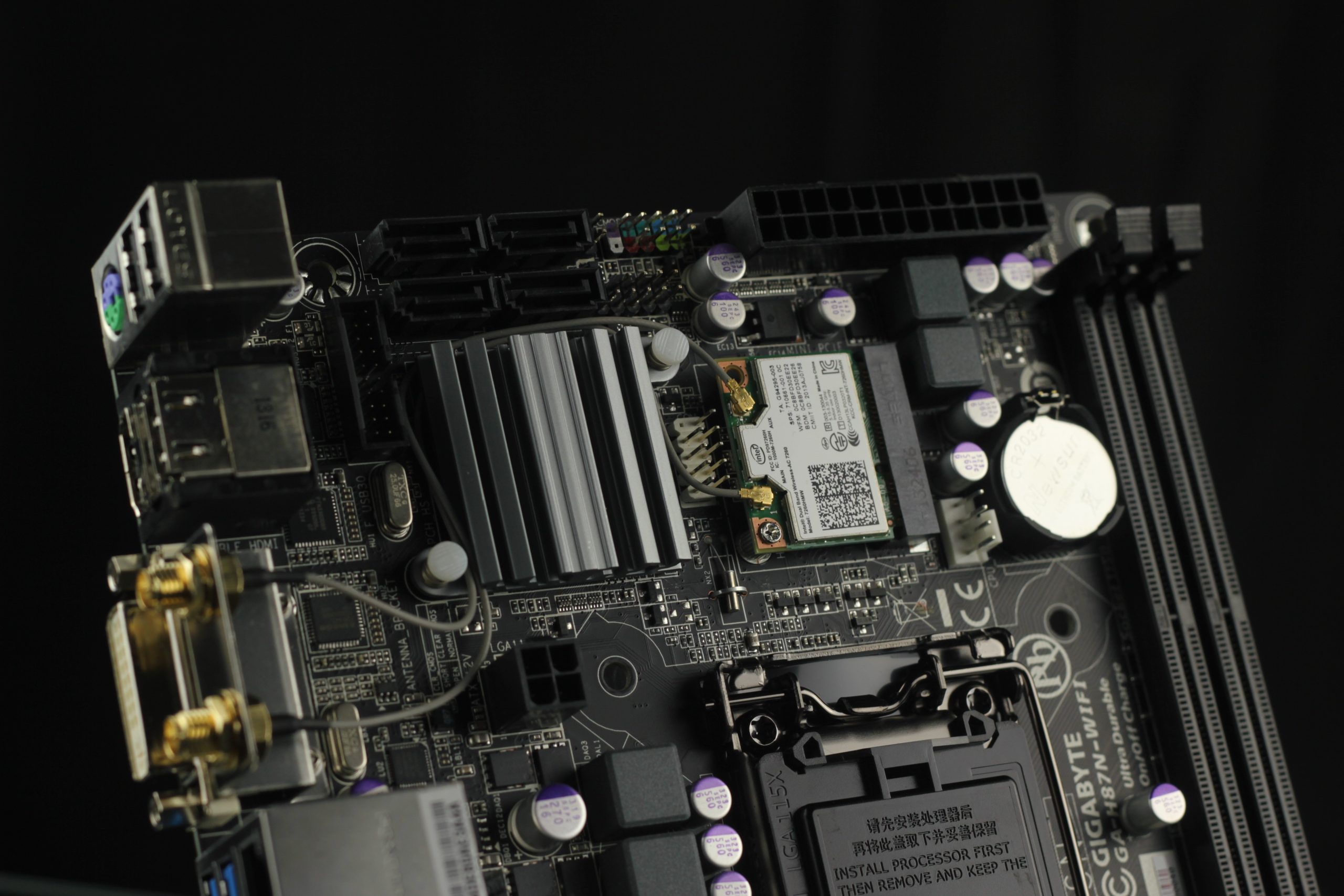

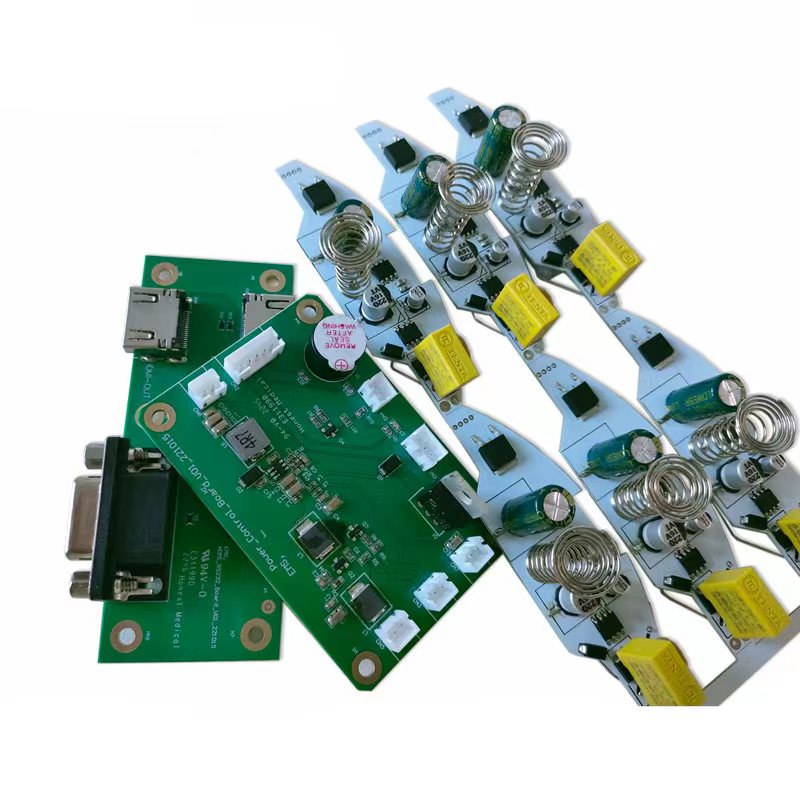

Security Control Panel Board

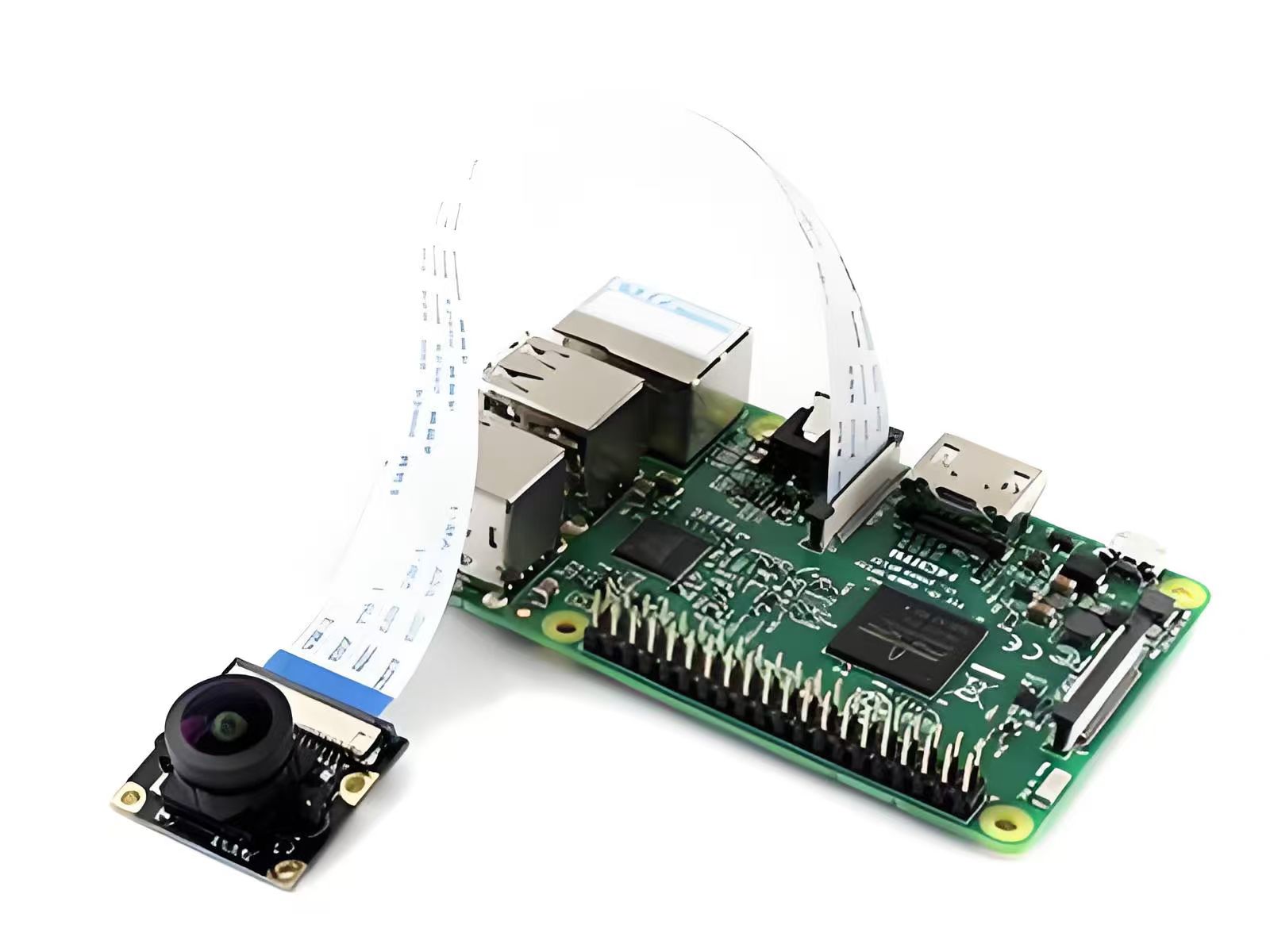

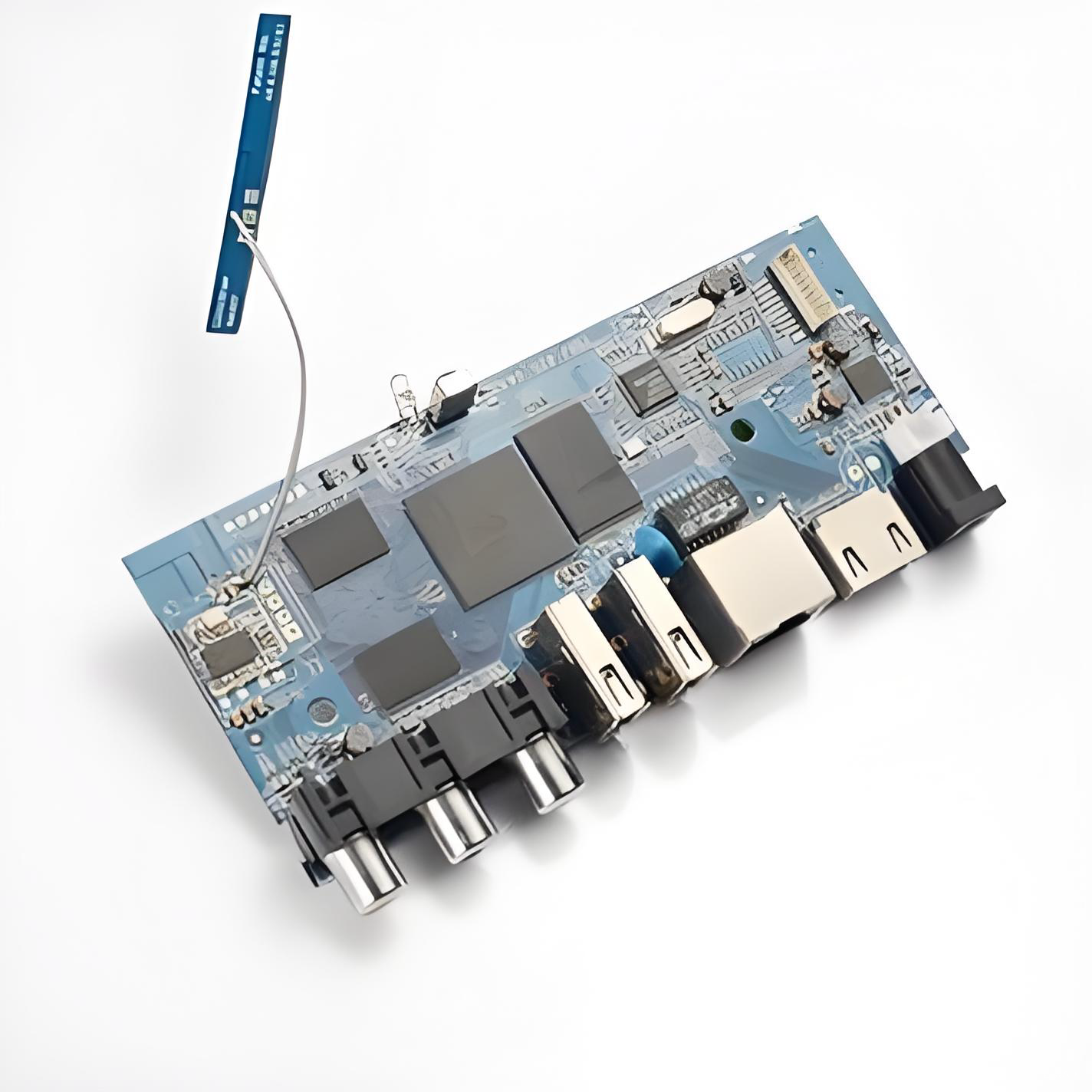

High-definition Security Camera PCBA Board

Security Monitoring Control Panel Board

Security Control Panel Board

Product Details

Introduction

Security and Surveillance PCBA refers to the specialized manufacturing and assembly of printed circuit boards that serve as the operational heart of modern protection systems. These assemblies demand extreme reliability, real-time processing capability, and resilience in continuous operation to support critical functions such as high-resolution video capture, intelligent analytics, and secure data transmission.

We deliver comprehensive, one-stop PCBA solutions for the complete security ecosystem, including IP cameras, access control systems, alarm panels, and NVR/DVR equipment. Utilizing advanced SMT manufacturing, rigorous quality assurance, and expertise in high-speed and thermal-optimized designs, we ensure stable performance and rapid deployment for our partners. Our complete service offering—spanning PCB fabrication, component sourcing, assembly, testing, and system integration—is engineered to meet the stringent requirements of professional security applications.

The Foundation of Protection Systems

Security PCBs are designed to be the nerve center of protection devices, handling complex tasks from image processing and pattern recognition to instant alarm triggering. These boards are characterized by their robust architectures, which typically include:

- High-Performance Video Processing: Supporting advanced image sensors, video processors, and AI chips for facial recognition, motion detection, and behavioral analysis

- Multi-Interface Connectivity: Integrating various communication interfaces including Ethernet, PoE, Wi-Fi, and cellular modules for flexible deployment

- Power Management Systems: Ensuring stable power distribution and backup power support for 24/7 operation

- Environmental Durability: Designed to withstand temperature variations, humidity, and continuous operation in demanding conditions

3. Functions:

The core functions of the control board revolve around coordinating and managing equipment functions, specifically including:

- Basic Control: Enabling basic operations such as starting, stopping, and adjusting parameters of equipment;

- Intelligent Management: Ensuring efficient and stable operation of equipment, such as intelligent temperature control, remote operation, and multi-segment timing for electromagnetic heating boilers;

- Access Control and Recognition: Multimodal recognition, rapid response, and high-capacity storage for access control board verification;

- System-Level Management: Signal acquisition, feedback, and overall system coordination in scenarios such as building automation and LiDAR.

The assembly of these critical boards requires not only precision manufacturing but also deep understanding of signal integrity, thermal management, and long-term reliability—essential qualities for building trust in security and surveillance solutions.